The Furnas 14CF32AA Wiring is a well-known motor starter used for controlling industrial machinery and motors. Designed with durability and reliability in mind, the Furnas 14CF32AA is widely used in a range of applications, including HVAC systems, compressors, pumps, and other heavy machinery. Whether you’re installing it in a commercial setting or an industrial environment, understanding the wiring setup of the Furnas 14CF32AA is essential for safe and efficient operation.

In this article, we will explore the specifics of Furnas 14CF32AA wiring, covering installation, wiring diagrams, setup, and best practices. This guide is designed to help both professionals and DIY enthusiasts navigate the wiring of this popular motor starter effectively.

Overview of Furnas 14CF32AA Motor Starter

The Furnas 14CF32AA motor starter is part of Siemens’ legacy Furnas line, known for its reliability and ease of maintenance. It functions as an electro-mechanical switch, automatically controlling motors by starting, stopping, and protecting against overloads.

| Specification | Description |

|---|---|

| Model Number | 14CF32AA |

| Type | Motor Starter |

| Applications | HVAC, compressors, pumps, machinery |

| Control Voltage | Typically 120V or 240V AC |

| Overload Protection | Available with thermal overloads |

The model often comes with built-in overload protection, a critical feature for preventing motor burnout and protecting equipment. Knowing the Furnas 14CF32AA wiring details is key to leveraging these features fully and avoiding operational issues.

Understanding Furnas 14CF32AA Wiring Basics

1. Main Power Connections

For safe and effective installation of the Furnas 14CF32AA, the power input should match the motor requirements. Most installations use either 120V or 240V, so always check the power requirements before wiring.

- L1 and L2 are the primary input terminals for connecting the line voltage.

- T1 and T2 are the output terminals, connecting directly to the motor.

2. Control Circuit

The control circuit allows the motor starter to turn the motor on and off remotely. Wiring the control circuit correctly is critical, as it controls the start-stop mechanism of the motor.

- The control circuit is wired to a start-stop button or switch, often located at a convenient distance from the motor.

- Commonly, a start button (NO) and a stop button (NC) are connected to the control circuit, creating a safe way to operate the motor.

3. Overload Relay Wiring

Overload relays provide protection against excessive current, a vital feature in heavy-duty applications. The Furnas 14CF32AA includes overload relays with adjustable settings to match the specific motor’s rating.

- The overload relay is connected between the motor and the main terminals, typically through T1 and T2.

- Wiring the overload correctly ensures the motor stops in case of current surges, preventing equipment damage.

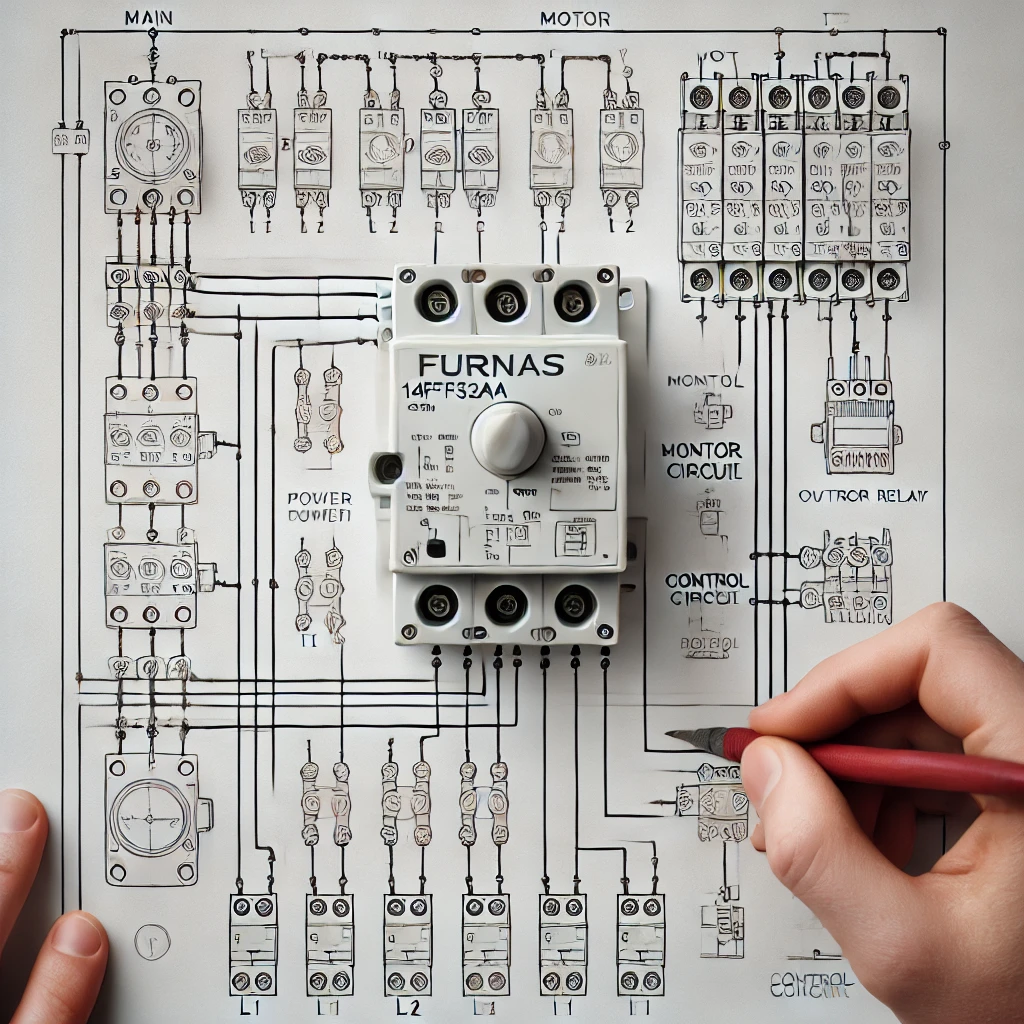

Wiring Diagram for Furnas 14CF32AA Motor Starter

The following is a standard wiring configuration for the Furnas 14CF32AA:

Understanding the wiring diagram for the Furnas 14CF32AA can help ensure proper connection and safe operation. Following manufacturer-provided diagrams is critical for specific applications, as minor adjustments may be necessary depending on the setup.

Step-by-Step Guide to Wiring the Furnas 14CF32AA

Step 1: Gather Necessary Tools and Materials

Before beginning the wiring process, gather the following tools and equipment:

- Screwdrivers

- Wire strippers

- Voltage tester

- Wiring connectors

- Protective gloves and safety goggles

Step 2: Turn Off Power

For safety, always switch off power at the main breaker panel before starting any wiring work on the Furnas 14CF32AA. This will prevent accidental shocks and protect your equipment.

Step 3: Connect Main Power Leads

- Identify the line voltage of the power supply (either 120V or 240V).

- Attach the line leads (L1 and L2) from the power source to the respective terminals on the Furnas 14CF32AA.

- Tighten all connections securely to avoid loose wiring, which can cause arcing and potential hazards.

Step 4: Connect Motor Leads

- Connect the motor leads to T1 and T2 terminals on the Furnas 14CF32AA.

- Verify the motor’s wiring configuration matches the power supply requirements.

- Tighten connections and check continuity to confirm secure connections.

Step 5: Install Overload Relay

- Insert the overload relay between the T1 and T2 terminals and the motor.

- Adjust the overload setting according to the motor’s rated amperage.

- Verify connections and secure all wiring to prevent movement during operation.

Step 6: Wire the Control Circuit

- Connect the start button to the control circuit, wiring it as a normally open (NO) switch.

- Connect the stop button to the control circuit, wiring it as a normally closed (NC) switch.

- Ensure all connections are secure and the buttons are accessible for operation.

Step 7: Test and Troubleshoot

- Restore power to the circuit and test the start and stop functions.

- Observe the motor for proper operation, checking for any unusual sounds or overheating.

- Test the overload relay by running the motor for a short period and observing its response to high loads.

Tips and Best Practices for Furnas 14CF32AA Wiring

- Double-check voltage and current ratings: Always match the power supply and motor requirements with the motor starter’s specifications.

- Use proper wire gauges: Selecting the correct wire gauge for your setup ensures optimal power transfer and reduces the risk of overheating.

- Secure all wiring: Loose connections can cause arcing, leading to system failure or fire hazards. Tighten all terminals and secure wires with ties if needed.

- Inspect regularly: Over time, wiring connections may loosen, especially in industrial environments. Inspect periodically for wear and tighten connections as needed.

- Follow local code: Always adhere to local electrical codes and safety regulations, especially for industrial installations. Consulting a licensed electrician is recommended for more complex setups.

Common Issues and Troubleshooting for Furnas 14CF32AA Wiring

- Motor Won’t Start

- Check the control circuit wiring and ensure both the start and stop buttons are functioning properly.

- Inspect the overload relay and confirm it is correctly rated for the motor.

- Overload Relay Trips Frequently

- Verify the relay’s amp rating and adjust it if necessary to match the motor’s operating range.

- Check for obstructions or load issues that may be causing excessive current draw.

- Excessive Heat in Motor Starter

- Ensure all connections are tight and wires are properly rated for the current.

- Avoid bundling wires, as this can cause heat buildup in tight spaces.

- Control Circuit Fails to Engage

- Test the start and stop buttons for continuity, and replace if necessary.

- Check the control voltage to ensure it matches the starter’s requirements.

Conclusion

The Furnas 14CF32AA wiring setup is straightforward but requires careful attention to detail and adherence to safety protocols. By following the wiring diagram, verifying all connections, and utilizing the correct tools and materials, you can ensure a successful and reliable installation of this motor starter. Proper setup will provide longevity and efficiency, enhancing the performance and safety of your machinery.

Whether you are a technician or a facility manager, knowing the ins and outs of the Furnas 14CF32AA will empower you to troubleshoot, maintain, and operate your equipment confidently. The Furnas 14CF32AA motor starter, when installed and wired correctly, becomes a valuable asset to any operation, providing safe and efficient motor control in diverse industrial settings.